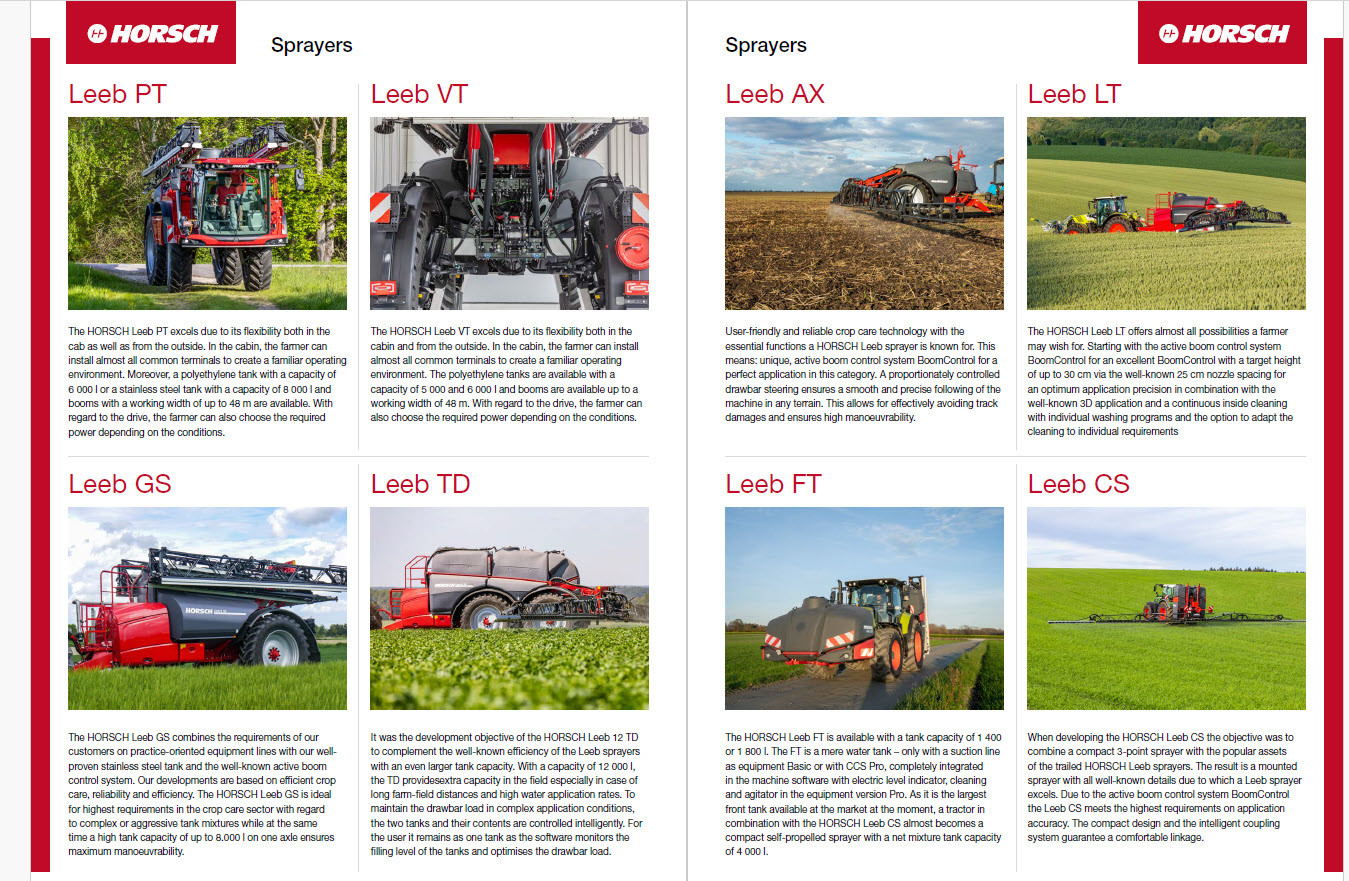

HORSCH Sprayers are available in Mounted, Trailed or Self propelled

Leeb CS - 3-point mounted sprayer - Crop Care | HORSCH

Leeb AX - Trailed sprayer - Crop Care | HORSCH

Leeb LT - Trailed sprayer - Crop Care | HORSCH

Leeb GS - Trailed sprayer - Crop Care | HORSCH

Leeb TD - Trailed sprayer - Crop Care | HORSCH

Leeb PT - Self-propelled sprayer - Crop Care | HORSCH

LEEB VT Variable Track Self propelled

Whenever special features are required, the HORSCH Leeb VT sets standards in crop care technology - whether high clearance, variable track adjustment, flexibility with the terminal, or simply maximum driving power is required.

The objective when developing the HORSCH Leeb VT was to achieve more with fewer machines in a shorter time – due to this strategy, farms today succeed in operating profitably and remaining competitive. As a manufacturer of crop care technology, our aim is to support farmers and entrepreneurs with efficient and precise technology.

Our R & D engineers do their best to provide appropriate solutions for the specific requirements on application technology in the crop care sector and to design a powerful and flexible machine for a wide range of applications. The result is a new generation of the Leeb VT, combining driving comfort, performance, and maximum application efficiency. The Leeb VT leaves nothing to be desired and offers more possibilities than ever before: variable track adjustment, more clearance, more driving comfort, greater climbing ability, more options with regard to the working width. In short: the Leeb VT offers an almost unlimited variability for highest demands on technology as well as on driving comfort.

Due to the possibility to customize the control terminal to the farmer's preferences and requirements in the cabin, operation in the familiar environment is easily possible. The joystick, developed especially for a self-propelled crop care sprayer, shows all necessary functions clearly and also allows the driver to freely assign the buttons to be able to adapt the machine even more individually. All these solutions help to provide the driver with a pleasant working environment, thereby increasing efficiency and performance. The well-known components that make a HORSCH Leeb sprayer unique remain the same. The powerful rotary pump with 1 000 l/min ensures highest suction rates and short filling times. Due to the active BoomControl control system, the liquid is then placed without drift and precisely on the target.

- Extremely comfortable chassis ComfortDrive: hydropneumatic individual wheel suspension with active level control

- Variable track adjustment from 1.80 m to 2.40 m

- High continuous ground clearance up to 1.30 m in field mode

- Practical control terminals and an ergonomic joystick for an intuitive operation, perfectly adapted to the application requirements

- Continuous inside cleaning CCS Pro with electrical valves and external control terminal, spraying and cleaning functions can be controlled in the cabin

- Uncompromising driving comfort: due to the individual suspension of all four wheels on slide frames, driving comfort is at car level. Even during fast cornering in roundabouts or on headlands, the Leeb VT remains stable due to the cross-linking of the axles.

- 50:50 weight distribution: due to the balanced weight distribution of 50% on the front axle and 50% on the rear axle in working position, compaction is actively prevented without affecting traction.

- Almost no limits: due to several available drives, there are almost no limits for the VT. With the standard drive OptiGear with a displacement of up to 190 cm³ per axle, the Leeb VT achieves top performance in the field as well as on the road.

- With PowerGear, the drive has a capacity of up to 230 cm³ and provides the customer with more power and performance reserves.

- Innovative innovations like PrecisionSpray, the HORSCH LEEB pulse width modulation, for an even more precise application.

- HorschConnect allows for a full control of the machine and the current status of the machine - an intelligent telemetry solution.

Summary

- 5 000 l or 6 000 l polyethylene mixture tanks

- Very powerful, hydraulic all-wheel drive with automatic slip regulation system for the versioins OptiGear and PowerGear

- All-wheel steering

- Optimal weight distribution 50:50 front:rear in working position

- 50 km/h on the road at 1 500 engine revolutions

- Tyres up to ø 2.19 m possible

- Variable track adjustment from 1.80 m to 2.40 m

- Up to 1.30 m clearance

- Quiet, comfortable cabin with Cat. IV filtration system

- Centrifugal pump made of stainless steel with an output of 1 000 l/min

- You can choose between 5- or 7-sect. booms

- CCS or CCS Pro water system with powerful rotary pump (1 000 l/min), continuous inside cleaning and other automatic washing programs

- 3" fittings suction-side

- Little drift due to automatic boom control system BoomControl and consistent target area height even at high operational speeds

- 25 cm nozzle layout for optimum wetting

- Powerful induction hopper

- Can be optimally adapted to the requirements of the farm due to its high versatility

- Compatible with different steering systems

BoomControl Pro

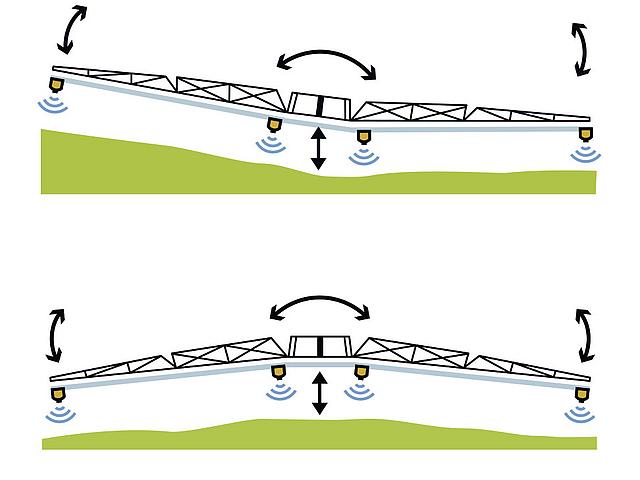

- Automatic BoomControl to maintain the exact, lowest possible working height even at a high operational speed and in very hilly terrain

- Safe and stable BoomControl below a target area height of 40 cm

- Prerequisite for minimum drift

- Boom is completely decoupled from the vehicle

- No compromise between damped and freely suspended boom

- Active adaption of the boom via the height control of the middle section

- Adaption to the terrain by the parallel angling of the boom arms in combination with the rotation of the middle section (control via four sensors).

BoomControl Pro

BoomControl extension

- Active adaption of the boom to the terrain due to two additional sensors

- To increase the field of vision, also ideal for row and ridge crops

BoomControl extension

BoomControl ProPlus

- Active adaption of the boom via the height control of the middle section

- Safe and stable BoomControl even below 40 cm

- Independent movement of both boom sections

- Additional independent movement (lifting and lowering) of both outside sections

Due to the sensitive responding behaviour of the proportionate control with 6 sensors the individual boom sections adapt “smoothly” to the contours of the terrain.

View

all news and offers

View

all news and offers